servo sizing precision leveling system

9.1 For the fine sizing and precious leveling.

9.2 structure servo motor, reducer, sizing roller, gateway, cylinder, gear, bearing, box, wall seeker, coupling, cardan shaft, synchronization devices

9.3 Use Yaskawa of Japan and the set of electrical device.

9.4 Servo motor 15KW( YASKAWA, Japan)

9.5 Use previous grinding gear reducer.

9.6 Use fixed ruler rod to make encoder rotate. PLC will calculate the length to reach a previous length.(upon the user)

The bridge rack

10.1 made of shelf plate and Anti scratch Cots

10.2 To guide the finished material in to shearing machine

shearing machine :(servo control continuous shearing)

11.1:servo controls to shear the steel plate.(2.0mmx1350mm)

11.2 motor rate: 22kw servo motor( wuxi xianfeng)

11.3 it adopt upper shearing to avoid burr.

11.4 add material passive rubber roller to avoid abrasion.

conveying system

12.1 lead the sheared plate to stacking platform.

12.2 consist of shelf, roller, reducer, reducer box, rod, conveying belt

12.3 Motor rate 5.5KW( Wuxi mingli)

Fan

13.1 function. Make a force to deduce the speed of material to avoid abrasion.

13.2 Motor rate 5.5kw (wuxi mingli)

Gathering and arrangement system

14.1 function: store the finished material and make it neat. Make reciprocating action.

14.2 Make of square tube, channel steel, walking motor, synchromesh gear, light bar, wire bar, swift, chain wheel, chain, ,cylinder, bearing, arrangement plate, stripper plate. Hand wheel.

14.3 The adopt plate length is 500mm-3000mm, width is 300mm-1250mm.

14.4 The width and length is adusted by moto, Motor type is Y80M1-4-0.55KW 2SET(Wuxi mingli), WBE1285-121-LD-YEJO.37KW 1SET(Wuxi Mingli), With electric brake.

X lift material storage platform.

15.1 Make of channel steel, steel and two cylinder realize lift (dia 125mm)

15.2 Arrange the finished material

15.3heright of material <400mm

15.4 loading weight MAX 10T

15.5 the Platform can arrange the material length 500mm-3000mm, width 300mm-1250mm.

unloading trolley

16.1 Transfer the neat finished material and pack.

16.2 Make of channel steel. Motor .walking wheel, late and bearing.

Hydraulic and pneumatic system

A Hydraulic SYSTEM

A-1 make of motor(11kw) , oil pump, Hydraulic valve, cylinder box , pipe and so on.

A-2 Contol the Hydraulic system of the whole machine.

A-3 System pressure 12MPA

A-4 Working pressure 8-9 Mpa.

B pneumatic system

b-1 The pipe is made of seamless steel . cylinder, valves are connected by PU pipe.

B-2 the cylinders are made under QGSsystem, and the sealing rings are made from shengyang keda research center

B-3 Air source treatment FRL and Electromagnetic reversing valve are made of Taiwan Yadeke.

18 Electric control system

18.1 Electric control cabinet 1set

Main operating cabinet 1set

assist operating cabinet 1set

combined type cabinet 1 set

18.2 realize the operating of the whole system. The main operating cabinet has the function of digital display, length determination, auto calculate, speed adjustment, manual feed, continuous produce and jam alarm.

7.2 structure:it consists of steel plate and profiled steel. There are paasive roller every 350mm on the rack (dia. φ60mm). Working length 1350mm.

centering device:

other parameters

1,flattening type:DC PLCS stopping sliting

2,power:380V/50Hz/3ph(it could be determined by buyer)

3,config.:electrical panel 1set

Main control panel 1 set

Assistant control panel 2 sets

Portable button case 1 set

4,Production direction:by customer(face to machine)

left-in and right-out right-in and left out

5,Plant area:about 22 meters ×8 meters

6,Operator:main skilled operator 1-2persons, assistant 2-3persons

Note:Specific number of operators depends on actual situation of customer's

7,color:computer-gray and orange pattern(for export plant)

Remarks: all the above parameters is primary data only for reference. If buyer has any other requirement, please contact us to make the best proposal.

Signature and seal for buyer Signature and seal for seller:

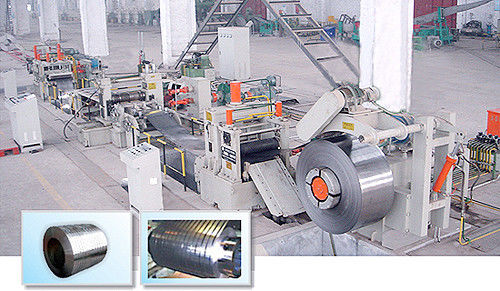

2. Equipment configuration

Equipment composition: